Transporting a high-precision machine is divided into the following three steps: securing the machine, avoiding knocks and unloading with extra care.

Supply

Tools

Linen or cotton yarn

Methods

1. Fixing

Machine tool transportation, must be firmly fixed in the transportation vehicle. The degree of fixation must be achieved: the machine tool in the car before and after the left and right can not move.

2. Avoid uneven road surfaces

In the transportation process, should be communicated with the land transport driver to avoid excessive ups and downs and bumps in the vehicle. Protect the surface of the machine tool to avoid being broken. You can use protective film or protective cloth to cover the machine tool to avoid surface scratches.

3. Unloading

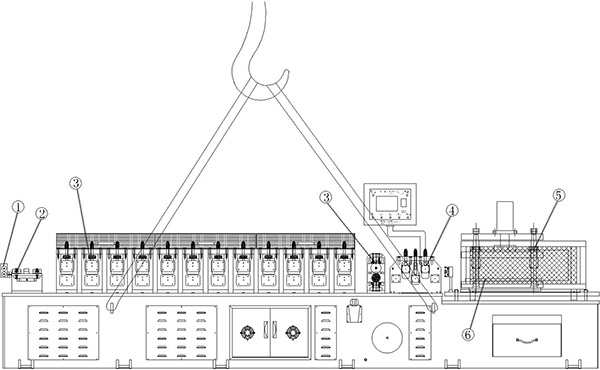

Before unloading, first check the external condition of the machine tool and count the accessories according to the packing list. If there is any problem, please contact us immediately. The bottom and sides should not be subjected to shock or excessive vibration when moving and lowering, so as not to affect the accuracy of the machine tool. When lifting, the machine should be balanced by padding with burlap or cotton gauze at the contact of the wire rope. (As shown in Figure 1). Observe whether the movable parts are well fixed before formal moving and lowering to prevent slipping.

Before and after moving the machine tool in the three stages, all need to pay attention to the details of the problem. In accordance with scientific and reasonable handling methods, can effectively avoid damage to the machine tool, to ensure that the machine tool into production work smoothly.

Keywords: roll forming machine

Originally published 03 Jan 2025, updated 03 Jan 2025.