For the hinge assembly machine 0 station indexing disc error between 1-2 mm and error more than 1-2 mm two cases, need to be differentiated to deal with.

1. How to deal with the 1-2 mm error when the indexing disc is normally indexed ?

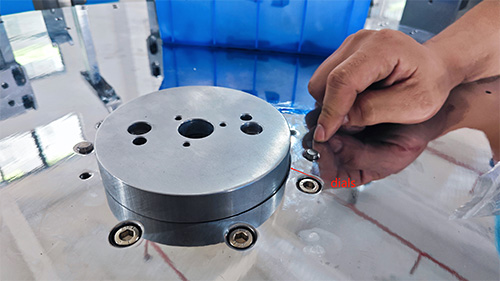

You can loosen the locking indexing disk 6 fixed screws. By fine-tuning the rotation of the indexing disk firmware, so that the indexing disk firmware and the product entrance to maintain a horizontal state. Then, lock the 6 set screws and click to manually rotate the indexing disk again. After rotating 8 equal parts of the mold, observe the same level with the entrance and exit, the problem is solved.

2. How to solve the serious offset of the indexing disc, exceeding 1-2 mm ?

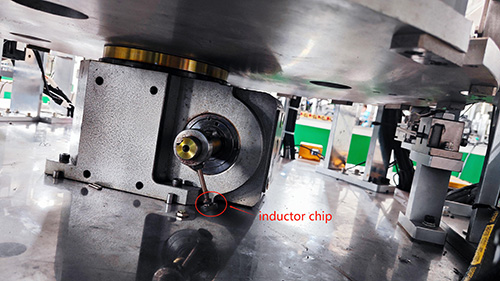

Check whether the indexing disk sensing is invalid, whether the sensing piece is off and loose. If the above problems occur, slowly fine-tune the sensor and the sensor piece, until the fine-tuning to the sensor and assembled products out of the mouth to hold the level.

The solution to the problem of 0 station abnormality is as above. According to different problems, follow the specific steps can be solved. The above method is applicable to all hinge assembly machines sold by our factory.

Keywords: hinge assembly machine

Originally published 28 Jun 2024, updated 28 Jun 2024.