When assembling, the rotary riveting is not in place need: manually adjust the scale value, rotary riveting reset, single action test, product observation.

How to solve the situation that the rivets are not in place when the four holes spring combination single needle riveting ?

1. First check the fixed position of the ejector pin and the mould two times the positioning distance. Click the riveting cylinder lift

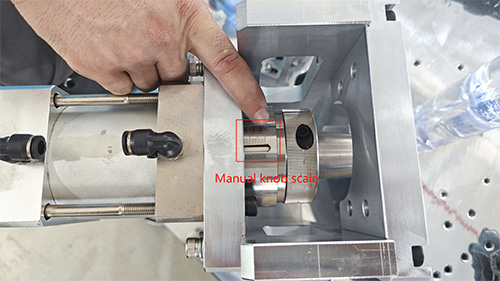

2. Manually adjust the length of the riveter scale value

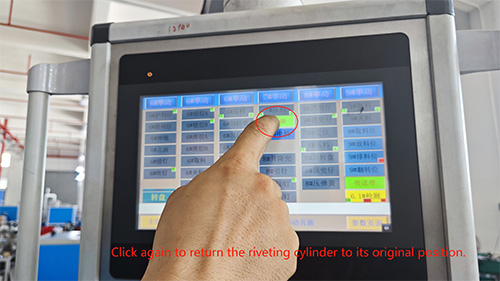

3. Click back to the original position of the riveting cylinder

4. Click on the single action test (that is, to complete the riveting position distance adjustment)

5. Remove the product to observe the adjustment of the required degree of rivet looseness and tightness

How to accurately oil the rivets ?

1. Oil injection quantitative

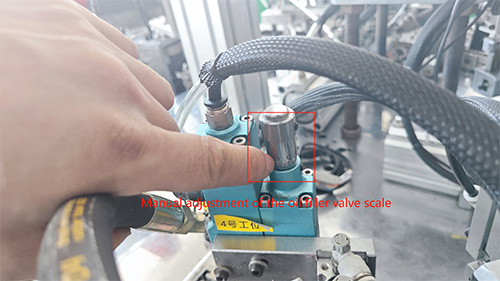

2. Adjust the oil injection valve scale value

3. Adjust the 5-station manual screen parameter settings to adjust the oiling valve time

Keywords: hinge assembly machine

Originally published 19 Jul 2024, updated 19 Jul 2024.