The operation of the slide rail assembly machine is easy, the steps are setting the parameters, automatic operation, and IO monitoring lights.

After assembling the slide assembly machine, please refer to the instruction manual in detail. Familiarize yourself with the structure of the machine, the function of each mechanism, transmission and lubrication parts. Before starting the machine, oil lubrication is required at each moving slide. Check the whole machine and make sure that it will not cause any mechanical damage during start-up before starting the machine. (This procedure is applicable to all slide assembly machines sold by our factory)

Supply

Slide Assembly Machines

Tools

Lubricating Oil

Methods

1. Setting parameters

After completing the above two basic operations, you need to set the required parameters before automatic operation. Including: time parameters and servo parameters. Parameter setting please customize the settings according to the product data and production efficiency. At the same time, please note that the position positioning and position reading should be valid after the servo reset is completed.

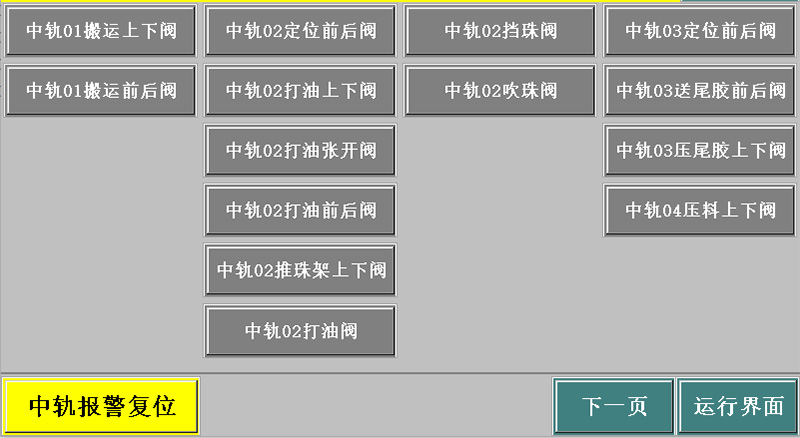

A. Manual operation (valid in auto-stop and pause states)

Manual operation page

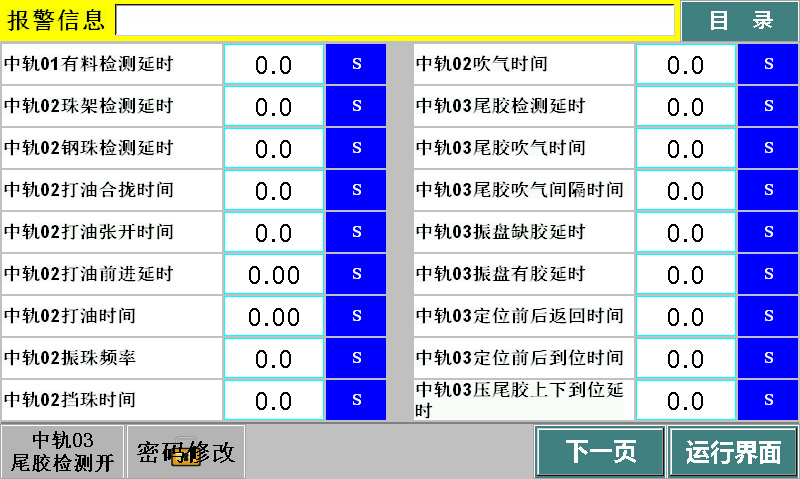

B. Parameter setting (please set the required parameters before automatic operation)

Time parameters

Servo parameters. Position positioning and position reading are valid only after servo reset is completed

Servo parameters are saved and written

2. Automatic operation

When the servo has been reset and all parts are in the original position, press the start button to enter the automatic operation state. If the conditions are not met, it will not be able to enter the automatic operation state. Therefore, please pay attention to the message on the touch panel. When a fault occurs, press the pause button to troubleshoot. After troubleshooting, release the pause and press the fault reset button to clear the fault and continue the automatic operation.

Note: When the outer rail station 5 is open, pressing the start button will start the middle rail station, outer rail station and inner rail station at the same time. When the outer rail station 5 is closed, pressing the start button will only start the center rail station and outer rail station. (When the inner rail station is activated when the outer rail station 5 is closed, the inner rail station 09 will be counter-pushed).

3. When entering into production, emergency situations require pressing the emergency stop switch.

perating interface

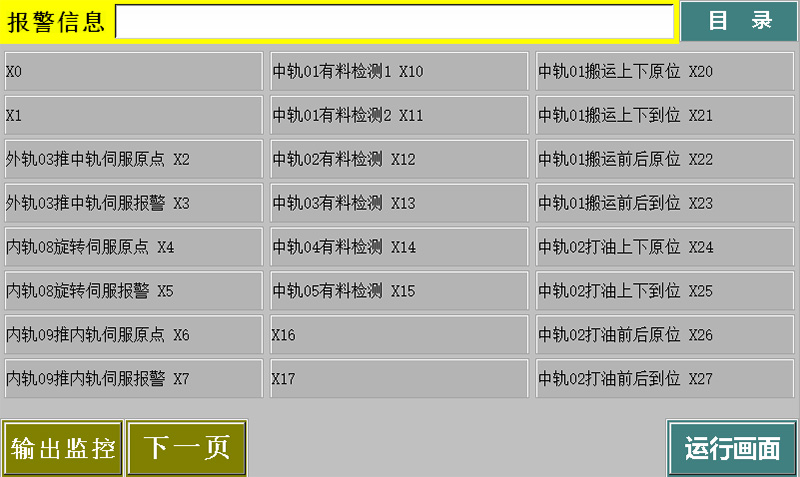

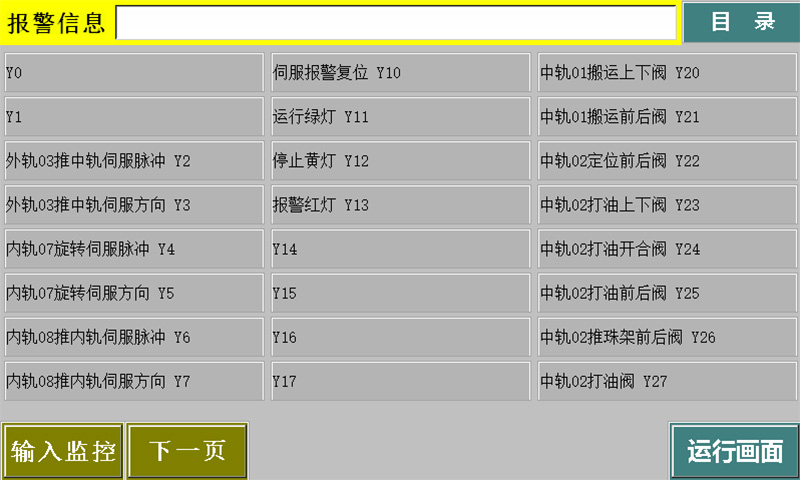

4. IO monitoring

When there is a fault, check the corresponding induction and solenoid valve to eliminate the fault, with a signal for green, no signal gray.

Input monitoring

output monitoring

The above is the slide assembly machine after installation and commissioning, the use of the process need to pay attention to matters.

Keywords: slide assembly machine

Originally published 06 Dec 2024, updated 06 Dec 2024.