Before operation, please rely on grounding, and install leakage protector with specifications of 40A~60A, and connect the incoming wire to the line row U V W (Note: This operation procedure applies to all molding machines produced by this factory)

Supply

Methods

1. Before starting, turn the "Power" selector switch to "On" position.

2. Press the manual button on the automatic screen of the touch panel.

3. Start the hydraulic pressure and check whether the rotation direction of the hydraulic pump and cooling pump is correct.

4. The hydraulic fluid pressure to 5Mpa, repeatedly press the panel "up", "down" button to the end of 6 to 8 times (to ensure that no mold case), exhaust the hydraulic cylinder and the oil pipeline in the air

5. Adjust the pressure to 8Mpa ~ 10Mpa.

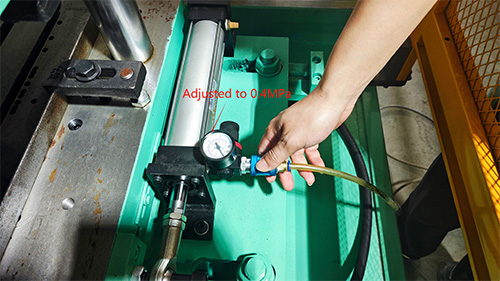

6. Connect the steel belt and air source, the air source to 0.4 Mpa

7. Tap the mobile button switch (up or down) for trial run

8. Load the mold, point through the mold, confirm that no scratch product phenomenon

9. Adjust the stamping depth and length, and then select the automatic button on the touch screen to start automatic operation.

Keywords: roll forming machine

Originally published 16 Aug 2024, updated 16 Aug 2024.