Maintaining a slide assembly machine requires: servicing the rails, cleaning the vibration discs, removing sewage, and checking the transport line.

Supply

A slide assembly machine

Tools

Cleaning cloth, lubricating oil, diesel fuel, alcohol

Methods

1. Maintain the table rail on a weekly basis. Regularly clean the table top rail with a cleaning cloth every week. Add lubricating oil or grease to ensure the normal operation of the rail.

2. Vibrating plate maintenance should be once a day. Before starting the machine every day, clean the material in the disk. First use diesel fuel to clean the disk surface dirt, and then use alcohol to clean the surface black residue can be.

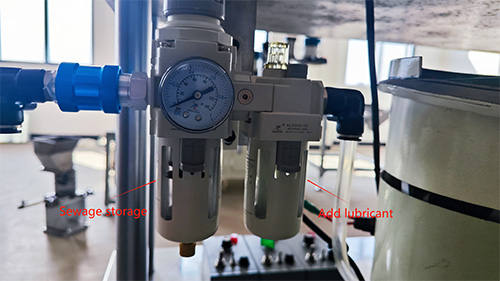

3. Compressed air filter valve (dichotomous) need to be checked every day. Add cylinder special lubricant in time to extend the life of the cylinder. At the same time, it is necessary to exclude the filtered sewage in the duplex at regular intervals.

4. The rotating shaft of the transportation line also needs regular maintenance. Observe the speed and sound of the rotating shaft at any time during the operation of the machine. If you find that the rotating shaft of the transportation line is not smooth or the noise is too loud, you should lubricate it in time.

5. It is also essential to check the belt of the transportation line every day. Observe the tightness of the belt and whether the belt is skewed when running. Ensure the service life of the slide assembly machine.

From eight years of experience in the production of slider assembly machines, the service life of a slider assembly machine depends on the method of use and maintenance. If the machine is regularly maintained according to the above methods, the productivity can be improved. (Maintenance methods are applicable to all models of slider assembly machines in our factory)

Keywords: slide assembly machine

Originally published 02 Aug 2024, updated 02 Aug 2024.