28 Nov 2024

There are seven differences between the Top model and the Economic type slide roll forming machine and you can choose the right machine for your needs.

1. Frame

Taiwan model adopts 14mm steel plate welded structure, paving panel 35mm, overall structure.

Economical type roll forming machine adopts 100*100 square tube welded structure, paving panel 30mm, overall structure.

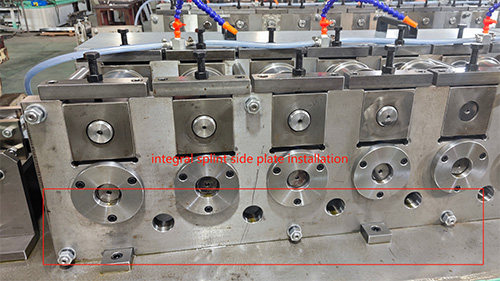

2. Side plates

Taiwan model - Main side plate is overall structure, the thickness is 38mm; Auxiliary side plate is independent roller seat, each group can be disassembled independently.

Economical type roll forming machine - adopts integral splint side plate installation, the thickness is 35mm.

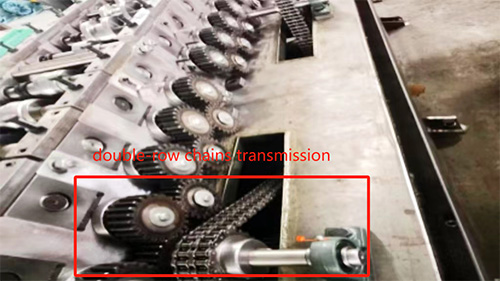

3. Transmission part

Taiwan model roll forming machine adopts gearbox independent transmission.

Economical type roll forming machine adopts double-row chains transmission.

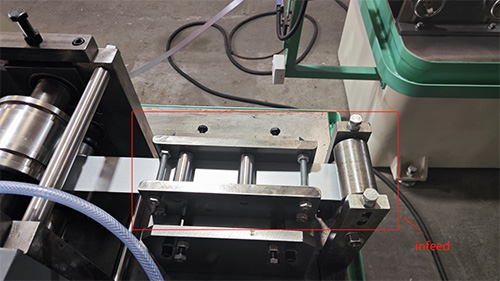

4. Die frame plate part

4-1. Taiwan model adopts 60mm×460mm×800mm die frame plate, guide post: Φ60mm.

4-2. Economical type adopts 50mm×400mm×800mm die frame plate, guide post: Ф50mm.

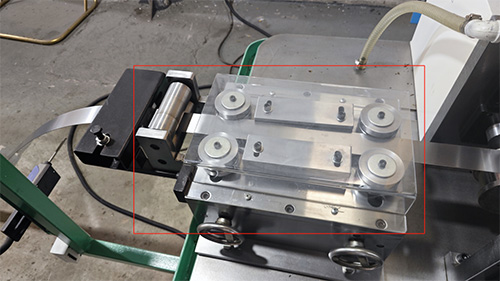

5. Feeder part

Taiwan model adopt splint plate fixed and guide wheel adjustment.

Economical type adopts splint plate fixed and adjustment.

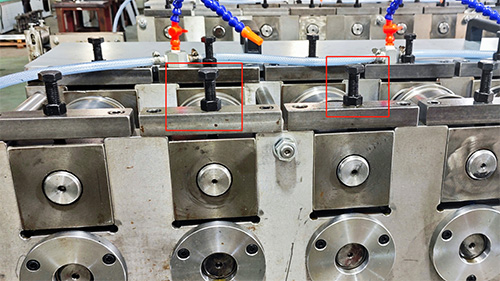

6. Roller adjustment part

Taiwan model have calibrated dial to adjust the accuracy.

Economical type neither has calibrated dial.

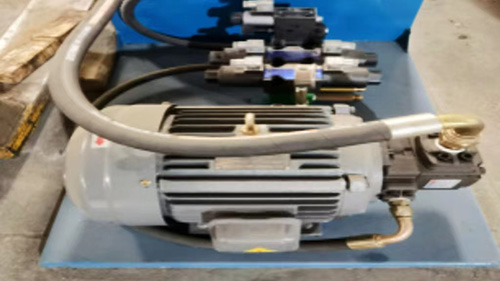

7. Hydraulic part

Taiwan model-Hydraulic parts inset into the frame, integral production.

Economical type - Hydraulic part is separate component.

8. Taiwan model machine has dust-proof protective cover and protective plate; but Economical type neither.

Keywords: roll forming machine

Originally published 28 Nov 2024, updated 28 Nov 2024.